Install the rubber expansion joint on the pipe to prevent the rubber joints from overstretching. It is better to install the rubber expansion joint immediately after the fixed bracket is installed. After the installation, the pipe behind the rubber expansion joint must be equipped with pipe guide bracket to support the pipe. Lock flange screws with the correct torque to allow the rubber joint to extend to its maximum displacement and to protect the surface of the product, install screws from the flange mouth where the rubber joint is connected to the flange. Threads and nut surfaces shall not be threaded.

High pressure resistant rubber joint

Installation instructions for rubber expansion joint:

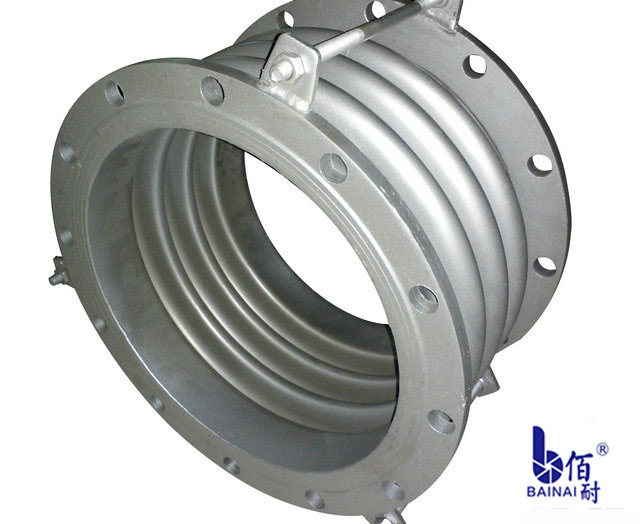

1. Rubber expansion joints shall not exceed the displacement limit during installation.

2. The pipe must have a fixed support or a fixed bracket, and the force of the fixed bracket must be greater than the axial force. In vertical installation and overhead installation, the two ends of the product shall be installed with corresponding fixed supports and force supports to prevent the work from pulling under pressure.

3. Mounting bolts shall be tightened symmetrically and gradually under pressure to prevent partial leakage.

4. Keep away from heat source during installation and do not use medium that does not meet the requirements of this product.

5. When installing rubber expansion joints, it is strictly forbidden to install beyond the displacement limit.

6. Install bolts symmetrically, gradually pressurize and tighten them to prevent local leakage.

7.1.6 for the working pressure above MPa, the bolts shall be installed with elastic pressure pad to prevent the bolts from loosening during work.

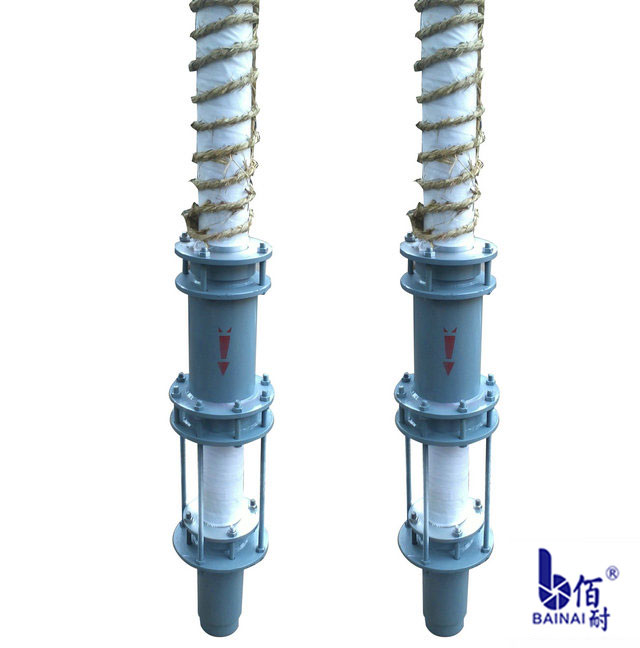

8. When vertical installation, both ends of the joint pipe shall be supported by vertical forces, and anti-pulling device can be adopted to prevent working compression pulling.

9. Rubber expansion joints should be installed away from heat source. Ozone area.

10. It is strictly forbidden to scratch the surface and sealing surface of the rubber expansion joint during transportation and loading and unloading.

"Ten points needing attention" for correct installation of rubber expansion joint

1. Before installation, the appropriate model must be selected according to the working pressure, connection mode, medium and compensation amount of the pipeline, and the quantity shall be selected according to the requirements of noise reduction displacement.

Second, pay attention to the regulation of pressure, when the pipeline produces instantaneous pressure and greater than the working pressure should choose a gear higher than the working pressure of the joint.

At the same time, when the pipeline medium is acid base, oil, high temperature and other special materials should be selected above the pipeline working pressure of a gear joint.

3. Flanges connecting rubber expansion joints shall be valve flanges or flanges conforming to GB/ t9115-2000.

Iv. Attention: rubber expansion joints shall bear pressure for the first time. For example, after installation under pressure or after long-term suspension, the bolts shall be re-pressurized and tightened before being put into operation.

Five, pay attention to the water temperature regulation, the normal medium is normal water temperature in 0-60 degrees Celsius, special medium such as: oil, acid and alkali, high temperature and other corrosive and

In the case of hard texture, should choose the corresponding special resistant material rubber joints, not blind string with or universal.

The rubber expansion joint shall be located at the side of the water pump when it is used at the inlet and outlet of the water pump. A metal reducing joint shall be installed between the rubber expansion joint and the water pump, and it shall be installed at the large diameter of the reducing diameter.

7. When the pipeline displacement is greater than or equal to the maximum compensation of joints, the number of joints shall be increased to parallel the displacement. It is strictly prohibited to adjust the out-of-tolerance of the pipeline.

Make the joint in the limit of perturbation displacement and deviation state, not to exceed the limit (expansion, displacement, deflection, etc.), the use of specific installation data is shown in the table below.

Eight, high-rise water supply or suspended water supply, the pipe should be fixed in the hanger, bracket or anchor, and can not let the joint bear the weight of the pipe and axial force, otherwise the joint should be equipped with anti-pull device.

Ix. When installing the rubber expansion joint, the bolt screw should be extended to the outside of the joint, and the bolt on the end face of each flange should be tightened evenly and repeatedly according to the method of diagonal pressure.

Prevent deflection. Screw joint should use standard wrench to tighten evenly, do not use a booster bar to add force to make the sliding wire, sliding edge and fracture of the joint, and should be checked regularly, so as to avoid loosening and causing disk-off or water seepage.

Ten, the regular and timely maintenance of rubber expansion joint, for example, in the use or storage of rubber joints, should avoid high temperature, ozone, oil and acid and alkali environment.

At the same time, considering the aging problem of rubber products, so outdoor or windward pipes should be built sunshade frame, strictly prohibit exposure to the sun, rain, wind erosion is very necessary.